Hi folks. I tried printing somethings using esun petg black for the first time on my standard Crs10 pro and was very successful, at 245c nozzle /70c bed. However after using 3/4 of the real, I am now having problems with my prints where after about 20 layers the nozzle clogs. No changes were made to the parameters, so I have no idea why this occurred.

Any advice would be much appreciated

Hi. Sorry to hear you are having trouble printing PETG. As you say that your CR-10S Pro is standard and that it has printed fine on the parameters you set then it makes me think it might be more of an issue with the filament itself. I haven’t had a ton of experience printing with PETG myself but I can think of some stuff to check.

-

How old is the filament?

I have found that older filament sometimes goes through patches where it will work well and then not work at all. I haven’t found it to be a very common issue but it does occur. -

Is your filament dirty?

If your filament is dirty or dusty it can cause clogging or extrusion issues. If you are worried about your filament being dirty then you can try this simple Filament Filter. -

Have you tried a different filament?

If it is just one roll of filament that you have been trying then it might be a problem with the roll. Try a different roll of PETG or a different type of filament if possible. -

Is it always clogging in the same place in the same model?

If this is the case it might be an issue with the sliced file so might be a good idea to try re-slice. I have had an issue where I slice a file and it starts printing fine but then suddenly fails. Very uncommon but I have had it happen. -

If using an SD card then consider trying a different card.

I have had a few instances where the culprit was actually a slowly dying SD card. Sometimes the SD cards that come with printers slowly fail/go corrupt and when this happens it can lead to random print failures for no apparent reason. -

If possible could you post a picture of the printer/print when it fails?

Sometimes an image can really help other members identify issues.

You might have already checked all these but in case you haven’t I hope it helps you identify the issue.

Happy making and I hope you get your issue sorted out soon.

Many thanks for the response.

The filament was bought about 2 weeks ago, and once I started printing with it, I have not changed the filament. I had successfully printed about 9 items of about 80g each and had just completed one and started the other which failed due to the clog. I would say that the filament is not dirty then. I have another green petg filament which i purchased at the same time and will give that a go, but first need to ensure I have a couple of spare nozzles first.

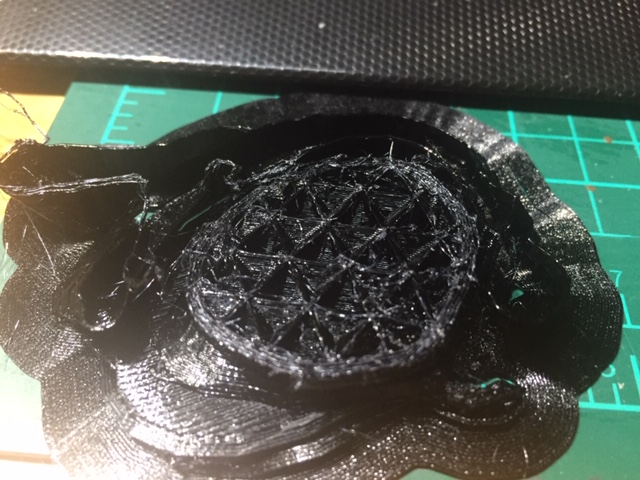

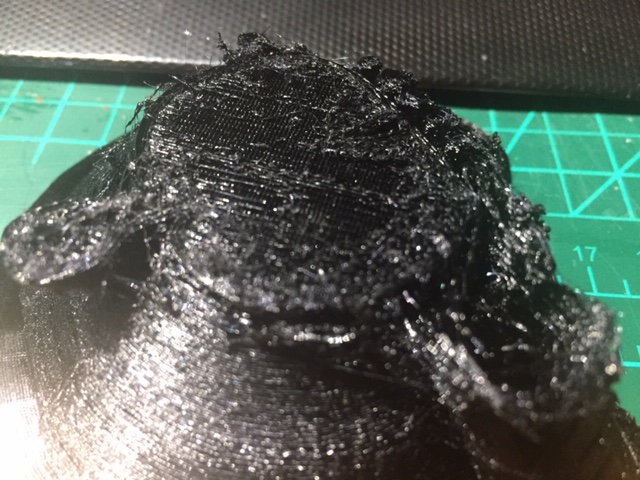

On reflection, retrieving the failed prints from file 13, I noticed they were different prints and had actually failed at different times in the print process. ( see attached photos).

I am still using the same card as what came with the printer, quiet a few years ago now. I will look at trying a different card.

When the first clog occured, I changed both the tube as well as installed a new nozzle. After the second clog, I just replaced the nozzle.

At present, I am 2hrs (30%) into a print using pla+ and all seems to be well.

Thanks again for the suggestions / advice.

What temp are you printing at?

Are you having problems with any other types of filament?

Have you checked the end of your Boden tube, it might need to be snipped?

Have you tried putting a fresh nozzle on, I like to use a different nozzle per filament type?

hi running at 245c temp, so should be ok there?

Having no problems with other filament, and this filament was printing perfectly before.

Replaced both tube and nozzle and still clogged.

Hello Mgorilla

I have a CR-10s Pro V2 and have printed with eSun and even Filament Factory PETG. The question I have is this on a standard Creality hotend? If so, I’d try the Luke Hatfield Bowden tube fix to remedy the clog. I did this on my Standard Creality hotend and had no clog problems ever.

[http://ecx.images-amazon.com/images/I/B17uAMNQ9QS.pdf]

Remember that the standard hotend can only print up to a certain temperature, if I remember correctly. I switched to a Micro Swiss (MS) full metal hotend, before I even attempted to print PETG. I have had great success with eSun and Davinci Labs PETG with the MS hotend.

I’d try 240°C and 80°C bed temps and no fan or very little fan at say 10% or 20%.

Good luck with the fix.

I had a similar problem printing flexible filament on my standard CR 10 S Pro. Bottom part fine and clogging further up. Turned out to be over-extrusion. Dialled “flow” in slicing down to 90%, and everyting was fine again.

Ok first off PETG with a PTFE lined hotend=bad idea and struggles all the way .

If you want to start printing PETG on the regular id suggest a all metal hot end and printing 250-255deg C on the nozzle.

Here is the problem with Printing that temp on a PTFE lined hot end

you are Printing way to close to close to the decomposition Temp of the PTFE and PTFE releases poisonous gasses when it starts decomposing from the heat .

you can keep the bowden setup just get a All metal hot end and stop worrying about the crap you are struggeling with now .

Now i have had my all metal hot end for just over a year i never had any materials related issues with PETG or my hot end , it was always a setting or something i mucked up

oh and have you tried sa filament PETG or filament factory PEtg they are really really good quality filament

Hope you get it sorted

Many thanks to all of the advice / suggestions. Much appreciated.

As I mentioned, i replaced the nozzle and cleaned up and started printing using pla+. The print came out ok, a bit stringy but usable after 6hrs. I then started another print and 20 mins in, there was a clog again, this time with pla+ running at 210c.

This morning, i decided to strip everything, clean fan (was not that bad, and also look at the gears (clean up etc). Cleaned the nozzle (could see through), removed standard hotend (cleaned everything) and reinstalled everything.

It is still clogging.

Thoughts:

- Gears look still good.

- Will replace hotend to a MS.

- Is nozzle getting to the stated temp? Do I need to replace thermister?

- Replace tube ( a bit short now after trimming).

Fan is still good as far as I can see - Over extrusion as mentioned above? Will play around with this

cheers

In my experience, nozzle clog is either a heat or a dirt problem.

I’d start by trying to print at a sliglty higher temperature. The only E-Sun I ever used was PLA and it had to print stupidly hot compared to other brands. It might be the same for PETG.

If that didn’t help I’d clean the nozzle nicely, or just plain replace it if it’s old (I use an E3D and they cost peanuts) and also clean the whole head, including pulling out the temperature sensor and cleaning that.

While it’s out, confirm that the temperature sensor is still accurate by dipping it in boiling water (Confirm that the temperature of the printer matches the one of your thermometer)

Also check that your fan isn’t blowing on the nozzle direclty.

PS: I see I’m late to the party  You got the same answer from everyone…

You got the same answer from everyone…

“I’d try the Luke Hatfield Bowden tube fix to remedy the clog”.

Dont do this , if you plan to print alot Of petg Just get a all metal hotend and stop struggeling

I have to agree with Andy here. In my experience Esun filament needs to run a little hotter than normal and got good results at 250 degrees. An all-metal hot end also helped a lot with getting a good consistent flow. I had similar inconsistent flow issues with 2 different brands of PETG and the Standard PTFE lined hot end. Running hotter solved my issue short term but toasted the PTFE which lead to more flow issues. Al metal heat break upgrade solved my issue completely.